Planimize Schedule Optimizer is running live in 2 fully automated fabs in France and Italy. It runs every 6 minutes to schedule several thousands of operations on several hundreds of resources, handling chained time constraints and maximizing productivity, tool efficiency and adherence to production plan, while minimizing lot transportation.

The software delivers excellent results on various industrial and academic benchmarks. This high performance is possible thanks to various innovative algorithms , some of which are published in highly recognized scientific journals. Moreover, high-quality schedules can be provided for large and complex scheduling problems in minutes thanks to the parallelization of algorithms, exploiting modern hardware.

Planimize is a software company, providing innovative decision-making tools, based on combinatorial optimization algorithms. We are specialized in scheduling software, in the semiconductor manufacturing sector.

Our general purpose is to improve the production efficiency of our customers. The decision-making tools we propose are derived from cutting-edge research and incorporate high-standard architecture, with cloud computing and web interface.

Planimize Schedule Optimizer is running live in 2 fully automated fabs in France and Italy. It runs every 6 minutes to schedule several thousands of operations on several hundreds of resources, handling chained time constraints and maximizing productivity, tool efficiency and adherence to production plan, while minimizing lot transportation.

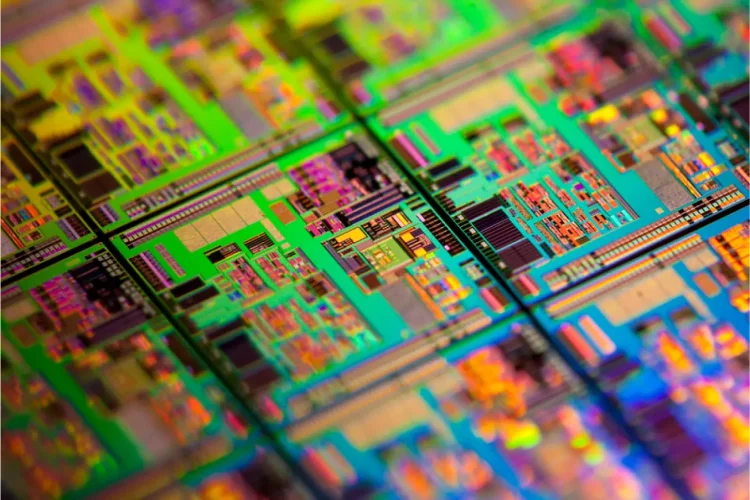

In complex manufacturing context, the scheduling of lots has a critical impact on the operational performance of factories, such as cycle time throughput, delivery time performance, and quality. For example, in wafer fabs, a single lot of wafers may go through up to 1,000 steps in different work areas. To create all the layers, each lot visits each work area frequently, leading to reentrant flows. In high-mix fabs, where hundreds of products are produced simultaneously, expensive production resources must be shared among lots of different products and lots at different stages. With shrinking chip sizes, ensuring high quality requires advanced process control systems that constrain the utilization of the resources.

To address these challenges, we offer a cutting-edge, generic and scalable optimization software for scheduling lots in different areas of factories. Generic, the solution can handle the most complex constraints (e.g., batching, queue times, reentrancy, auxiliary resources) and simultaneously optimize the most relevant performance measures. Scalable, the optimization engine can solve very large and complex scheduling problems.

Planimize Schedule Optimizer, implemented as a service that can be run in the cloud or on-premise, computes optimal scheduling decisions in complex manufacturing systems. Among the enormous number of possible decisions, the software finds those that simultaneously optimize the most important key performance indicators for the customer.

• Our algorithms ensure handling scheduling problems with thousands of operations and hundreds of resources.

• Multiple criteria optimized at the same time

• High-quality schedules computed in few minutes.

With our software, you get the customizable interface « Panelo » that provides you with a visualization of schedules, the optimization progress, and the key performance indicators which matter in your context

Our scheduling solution is developed closely with the semiconductor industry, which manages the most complex advanced manufacturing systems.

Initially used in semiconductor manufacturing, our solution was designed from the ground up for longevity and extensibility.

Thanks to our expertise, our solution can be adapted to other complex and capital-intensive industries.

Providing advanced optimization solutions for complex manufacturing requires listening to our customers and deeply understanding their challenges.

Research, innovation and performance are the main focus at Planimize.

Our expertise in deploying advanced analytics will be made available to our customers to ensure the potential of our solutions is realized.

Our R&D roadmap is defined by our customer needs that we aim to satisfy using state-of-the-art technologies.

© 2022 Planimize All rights reserved